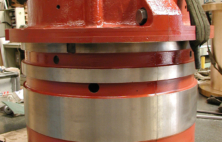

Babbitt bearings for cement factories are most of the time single pads of high dimension. They work at a low rotation speed (typically around 15 RPM) and are subject to many random shocks in crusher applications.

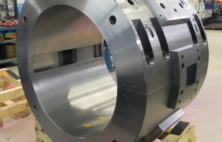

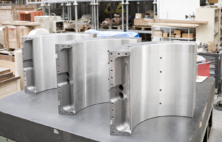

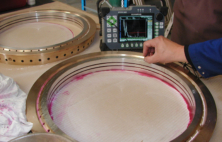

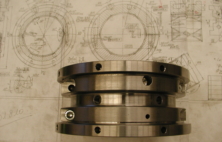

The shape of these bearings does not allow a centrifugal babbitting. They are therefore manufactured through a static pouring with specific tooling for each type of pad.

Complex geometry, the presence of cooling water chambers or the use of a cast iron support make the babbitting more difficult and impose a specific know-how as well as precise tuning.

You Industrie has a long experience of static pouring for small and big dimensions. YOU Industrie owns a stock of more than 100 molds and tooling sets, necessary to reply to the need of the cement industry.

The babbitt bearings of cement factories work at a low speed with irregular efforts in an agressive environment of cement dust, as opposed to most of other applications with high rotation speeds in a mechanics-favorable environment.

Lead-based babbitt metals are used as they are more efficient for such applications than stain-based babbitt.