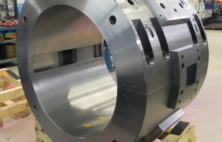

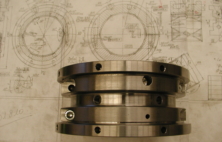

Hydrodynamic bearings are mechanical parts aimed at supporting and guiding rotors and similar mechanical shafts in turning machines

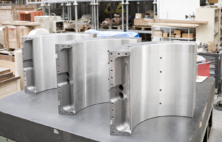

YOU Industrie provides plain bearings where rotors are supporte by babbitted bearing, as opposed to ball bearings, roller bearings or needle bearings.

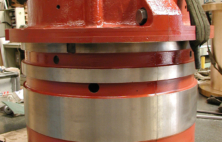

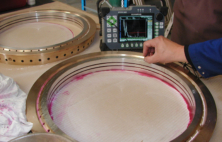

An oil film is maintained between the rotor and the babbitted bearing, which at some speed, ensures the supporting and separation between the 2 surfaces for a frictionless operation

In hydrodynamic bearings, the speed generates the oil film, when in hydrostatic bearings, that is an exterior pump that forces the creation of the same oil film. The quality of this oil film is crucial since an excessive heating and friction would destroy the babbitt layer (fusion temperature 290°)