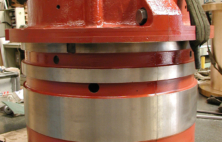

A plain bearing main role is to ensure rotation of shaft in turning machines. There is no sign of wear in a normal use. However, numerous start/stops as well as vibrations can generate sliding surfaces.

The wear produces temperature rises that become unacceptable for a correct operation. The babbitt bearing must therefore be dismounted and repaired with a new babbitting. In many applications, a babbitted bearing will last more than 10 years.

A secondary function of the babbitt bearing is to work as a “fuse” in case of malfunctionning or accident on the machine. These accidents bring a disruption of the oil film and an immediate heating. The babbitt metal of the bearing melts quickly to absorb the heating, giving necessary time to stop the machine before more damage is done. Since babbitt metal has a very low fusion temperature (around 250°), the rotors usually mad of steeel are hardly damaged during these emergency stops. A babbitt bearing is therefore “sacrificed” in order to protect the much more expensive rotor.

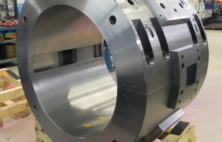

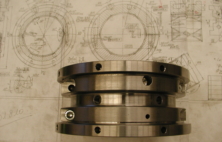

The original babbitt bearings can be repaired. These repairs are always more difficult to realize compared to new products since the old bearings typically present dimensions variations compared to new ones.

Outside diameters need to be machined back into the right tolerances since they have suffered deformation with the new babbitting thermal shock.

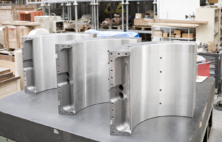

YOU Industrie developed a very specific know-how in this field and can repair the most complex babbitt bearings.

In 95% of cases, YOU Industrie can guarantee its repairs with a quality level identical to a new product.

Key factors of a repair are :

- expertise of the bearing, search of potential cracks

- analysis of the failure causes and possible improvements

- possibility to replace any kind of non standard babbitt metal

- replacement of cooling coils

- centrifugal or static babbitting

- renewal of toleranced diameters (through machining, metalisation, use of shims…)

- complementary work and technical improvements

- supply of accessories

- supply of CAD drawings

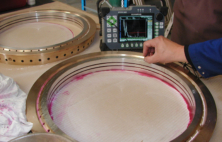

- Ultra Sonic control, Dy Penetrant control, and sometimes magnetoscopic control

- speed of intervention (24/7)

- urgent delivery